In this example we show the usage of the ’Dynamic General Motion’

technique in the context of a 3D Relay.

Estimated time: 1 h

Follow the steps:

This example is shown using 3D, but the technique is possible in 2D very

similar. The corresponding model in 2D is stored at the same folder

location, so it can be seen there how it is set up.

Estimated time: 1 h

Follow the steps to reproduce it:

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/6.CouplMotion/6.3Relay.zip

Open the part file ’relay3D.prt’.

Start Simcenter Pre/Post, create a new Fem and Sim File for 3D.

Switch off ’Create Idealized File’,

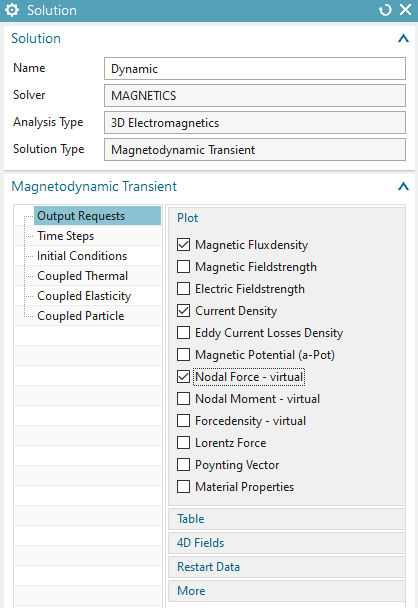

Chose Solver ’MAGNETICS’ and Analysis Type ’3D Electromagnetics’,

Choose Analysis Type ’Magnetodynamic Transient’.

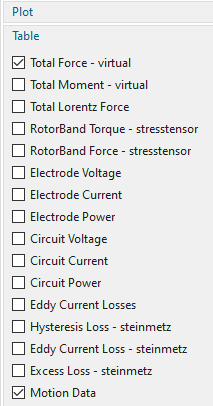

In register ’Output Requests’, ’Table’, activate ’Motion Data’.

Others can be activated as desired.

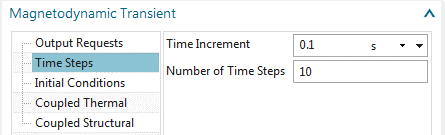

In register ’Time Steps’, select a time increment of 0.1 sec and

10 time steps.

Change to the Fem file.

In the following steps we create all 3D Meshes (all but the air gap). This will be done by tetrahedral elements and appropriate mesh collectors.

First, create mesh mating conditions. So, make all polygon bodies

visible, click on ’Mesh mating Condition’ ![]() , drag a window over the geometry, set the ’Mesh Mating

Type’ to ’Glue-Coincident’ (default), click ’OK’. Check, there will be

22 mesh matings created.

, drag a window over the geometry, set the ’Mesh Mating

Type’ to ’Glue-Coincident’ (default), click ’OK’. Check, there will be

22 mesh matings created.

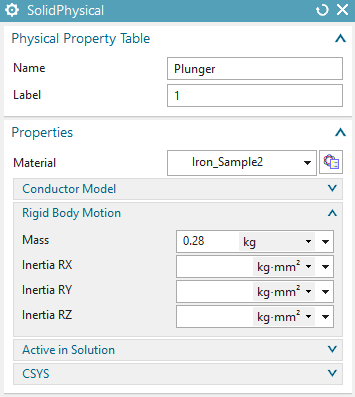

Then, mesh the Plunger with one fourth of the suggested mesh

size. Assign the material ’Iron_Sample2’ as well as a ’Rigid Body

Motion’ mass of 0.28 Kg.

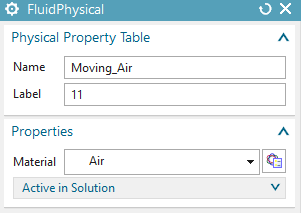

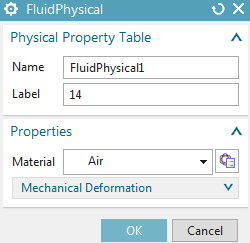

Mesh the (two) moving air stripes with one fourth of the

suggested element size. Use a ’FluidPhysical’ and assign material

’Air’.

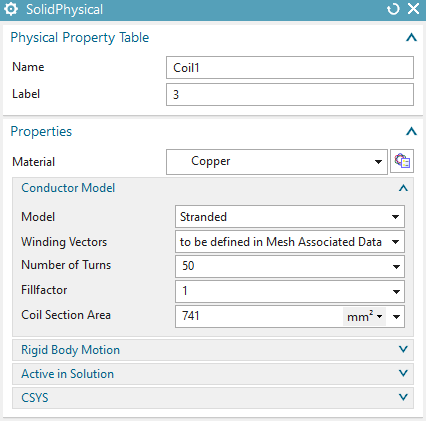

Mesh the first Coil with the suggested mesh size and assign

material ’Copper’. Also, set the ’Conductor Model’ to ’Stranded’ with 50

turns, a fill factor of 1 and a coil section area of 741 \(mm^{2}\).

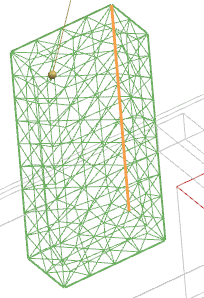

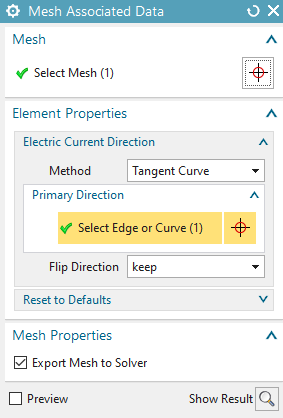

Edit the ’Mesh Associated Data’ of the coil mesh and define the

direction of current (use one of the z-dir edges. Take care that the

polygon body is shown.).

Proceed in the same fashion with the other three coils (meshing,

material and current direction).

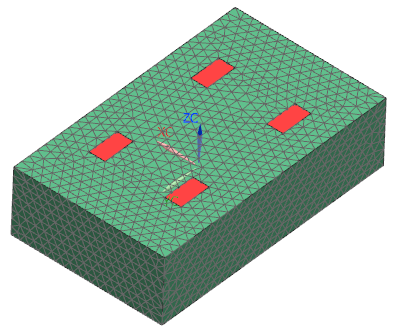

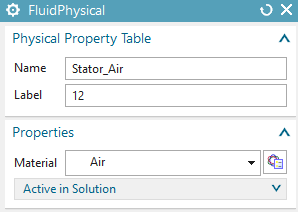

Finally, create a mesh with one third of the suggested mesh size

for the stator air and set the small feature tolerance to 2%. Again, use

the type ’FluidPhysical’ for this.

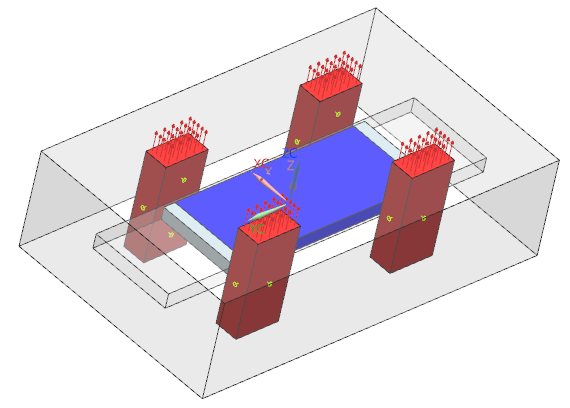

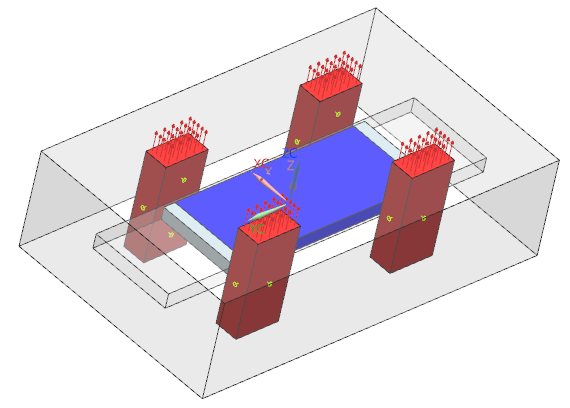

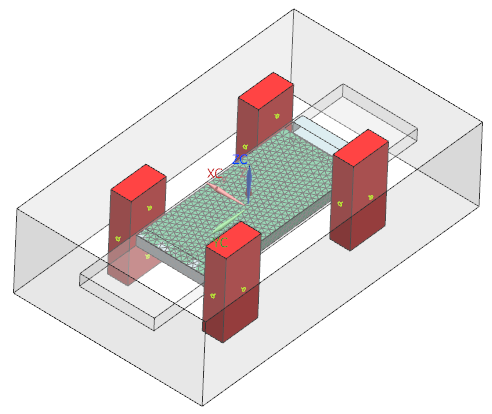

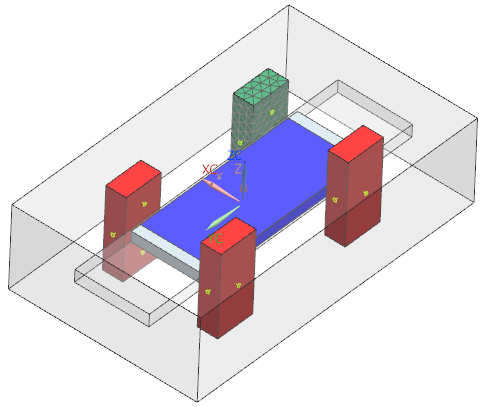

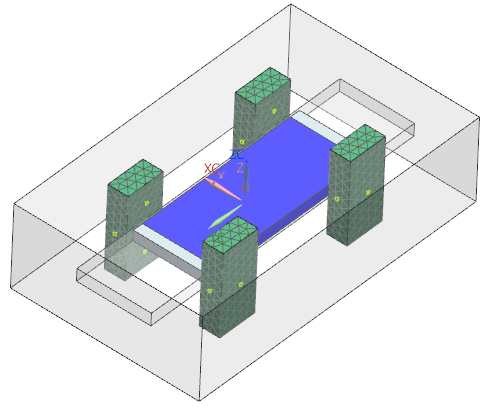

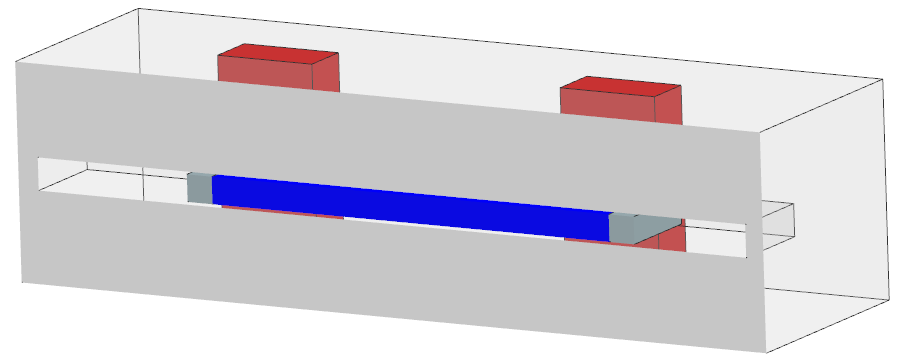

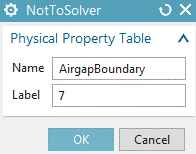

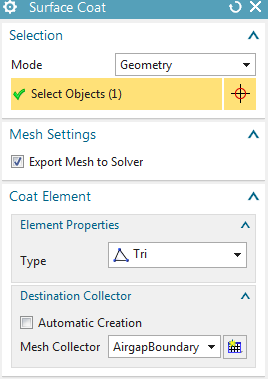

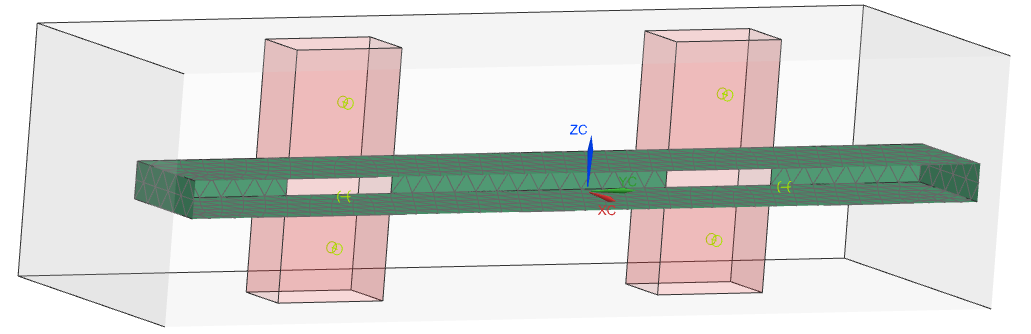

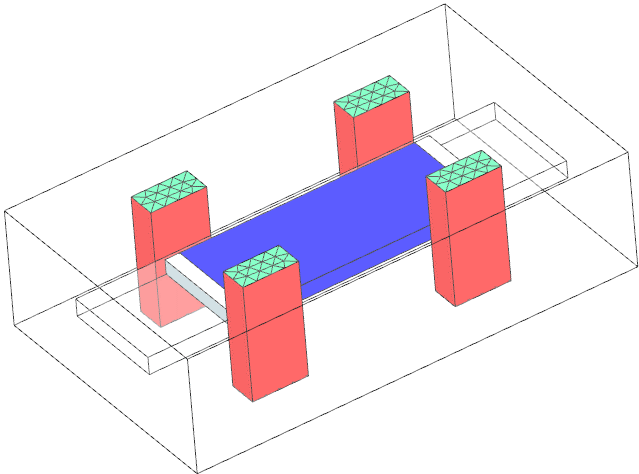

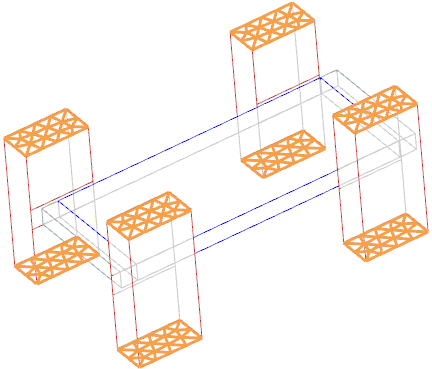

Following we do preparations for the 3D air gap mesh. E.g. the

mesh that will update with each movement step. Following picture shows

the plunger and how the updating air gap surrounds it. So, if the

plunger moves and the air gap is updated, a new simulation step can be

done.

This updating air gap mesh will be of type ’Solid from Shell Mesh’ and

therefore needs 2D boundary meshes from which it depends. Therefore, NX

Magnetics provides a feature that allows to recreate that mesh prior to

each solve. We will set up this feature now.

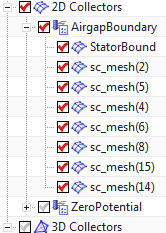

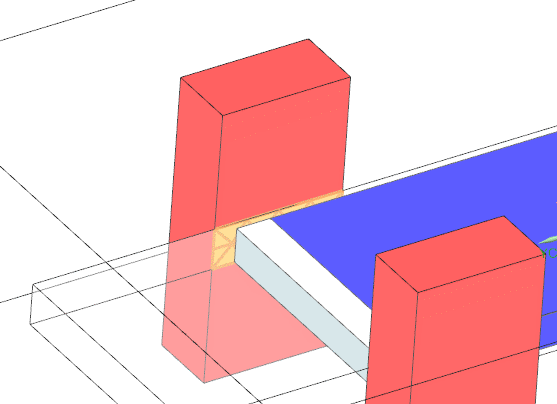

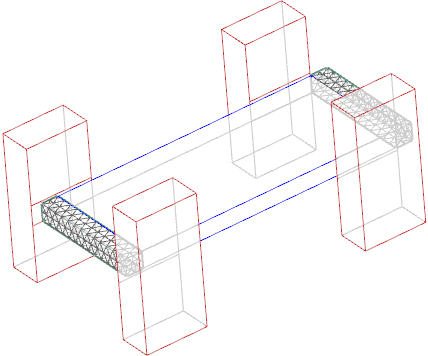

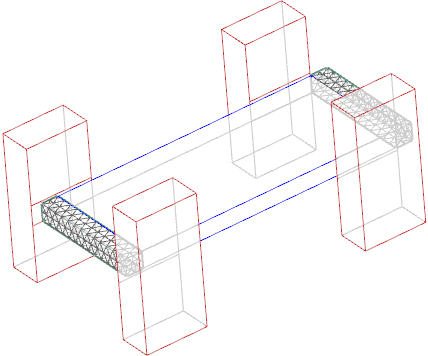

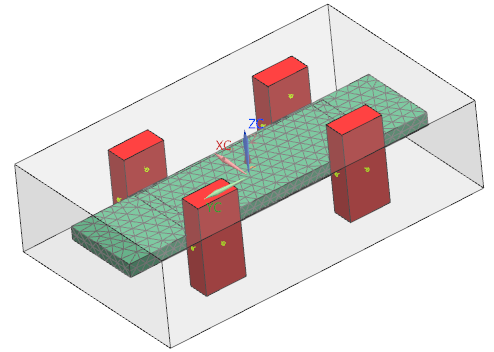

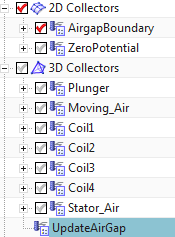

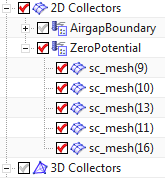

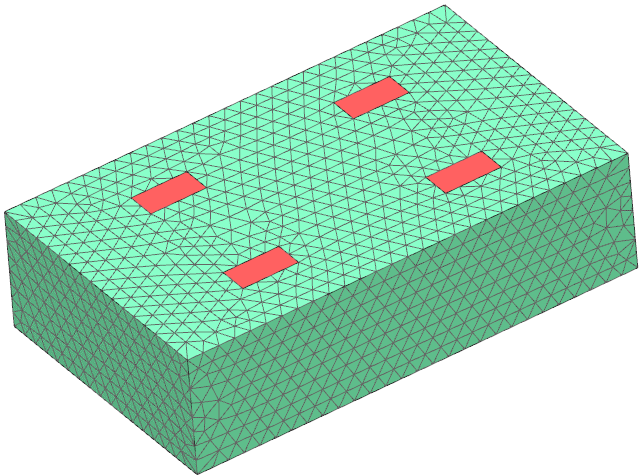

Following you create all boundary meshes of the updating air gap.

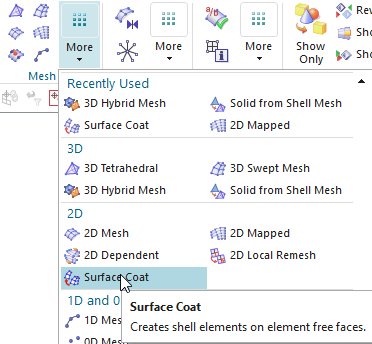

Therefore, you create surface coat meshes (picture below left) on all

faces that belong to the boundary of the air gap. The right side picture

below shows how the navigator looks after all the boundary meshes are

there.

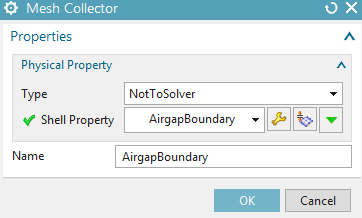

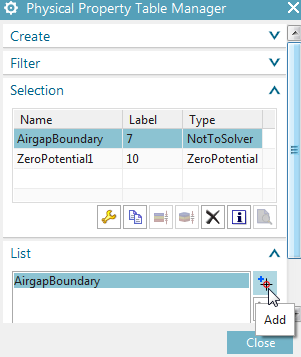

To collect the following meshes, first create an 2D mesh

collector, name it ’AirgapBoundary’. Use a physical of type

’NotToSolver’ because these meshes will act as borders only for the 3D

air gap mesh.

First, create a ’surface coat’ on the 4 inner side sections of

the four coils that are in contact with the moving air (see

below).

Next create surface coat meshes for the left (e.g. green mesh)

and the right surface parts of the moving air.

Then, create a surface coat mesh for the moving air.

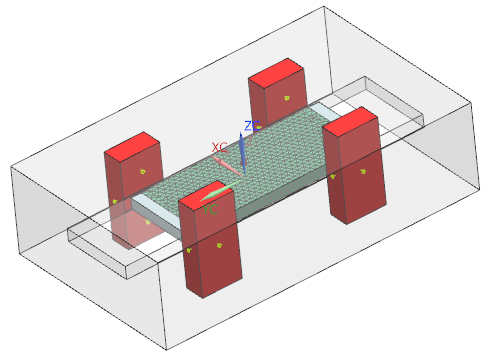

Finally, create a surface coat mesh stator bound air (that

provides the extend over which the air can move). For easier selection

of these interior faces of the ’Stator_Air’, use the helpful ’Clip

Section’ feature from toolbar ’View’. Select all inside faces of the air

as shown in the picture below (Note: You have to invert the clip section

to select the faces on the opposite side).

When all boundaries are visible, it should look like the

following picture.

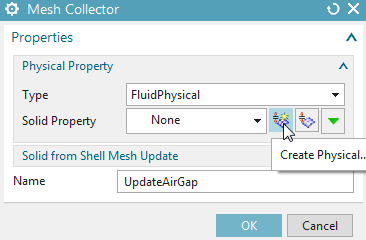

With these air gap boundaries being completed we now set up the automatically updating 3D air gap mesh:

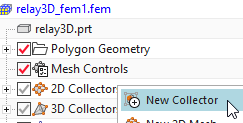

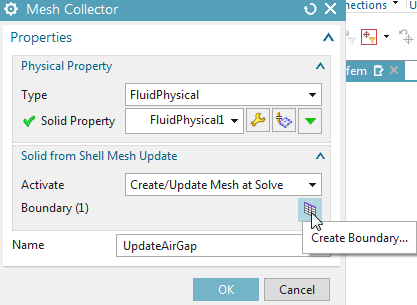

Create a 3D mesh collector.

Name the collector UpdateAirGap, set the physical type to

FluidPhysical, click Create Physical and set the material to Air. Click

Ok.

Back in the mesh collector dialogue expand the box ’Solid from

Shell Mesh Update’ and set the option Activate to ’Create/Update Mesh at

Solve’.

Click on ’Create Boundary’ and in the following dialogue select

the previously created physical AirgapBoundary that holds the 2D

boundary.

Click Close, Ok and the mesh collector is created. Notice that it contains all necessary information to create a Solid from Shell Mesh, but the mesh itself will be created at solve time. (Alternatively you can create the mesh manually now, it makes no difference).

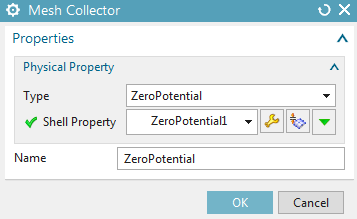

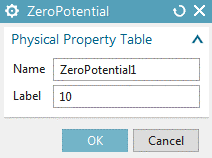

Now create all outer 2D surface coat meshes (equivalent as in the

last step). However, in contrast to the last step, use a physical

property of type ZeroPotential. Hint: We do this procedure in order to

fix the Boundary condition (i.e. ZeroPotential) directly in the .fem

file. However, this could also be done in a later step in the .sim

file.

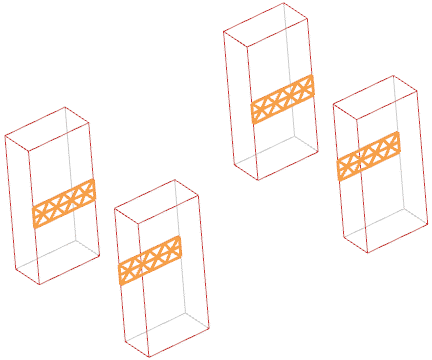

First, create surface coat meshes for the top and bottom sides of

all four coils (see picture).

Then create a surface coat mesh for the outer air.

Meshing is done, change to the Sim file.

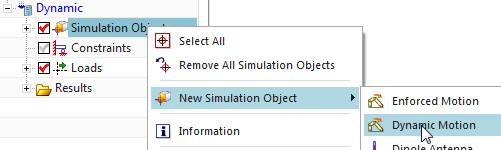

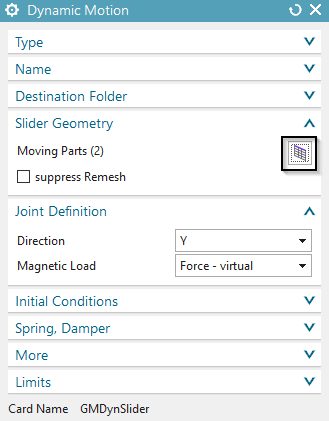

Create a Dynamic Motion to define the movement of the plunger.

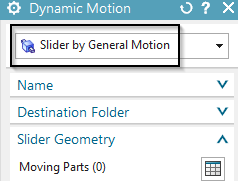

Create a simulation object of type ’Dynamic Motion’. Activate

’Slider by General Motion’.

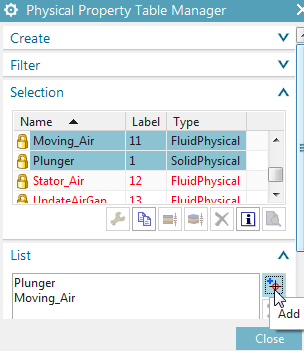

In the dialogue first define the Slider Geometry. Click on

’Create Moving Parts’ and add the two physicals Moving_Air and Plunger

that will move to the list. Click Close.

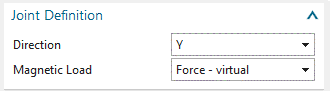

Back in the Dynamic Motion dialogue, set the Direction to Y and

accept all other defaults with Ok.

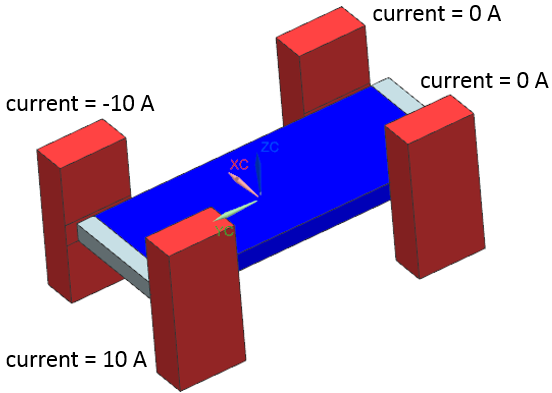

Define the electric currents on the four coils: Define zero

amperes on the two right coils (see picture) and define 10 and -10

amperes on the two left coils. This will result in a Y force on the

plunger.

Solve the solution.

Post processing.

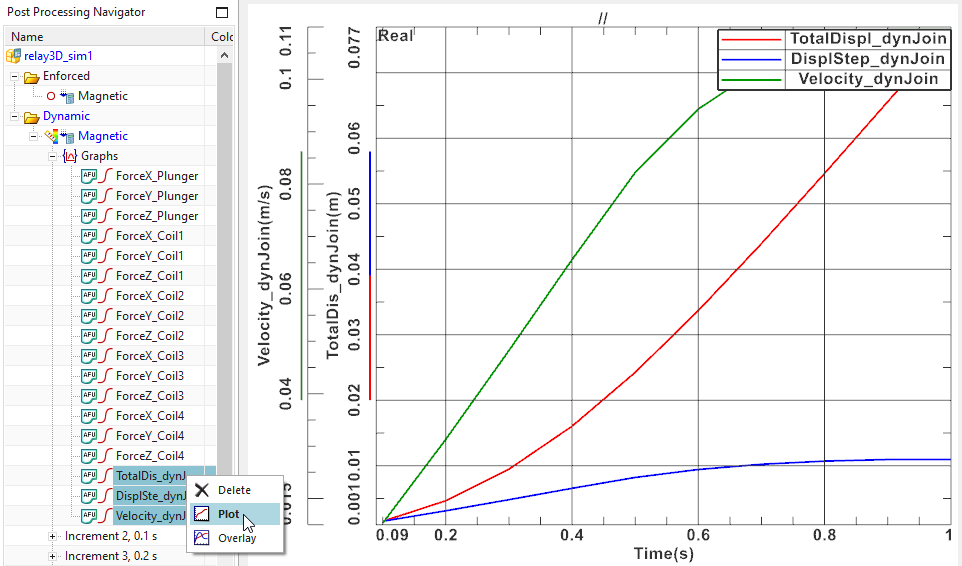

We first check the motion data result. This contains Total Displacement, Displacement Step and Velocity.

Open the associated result file in the post processing navigator. A list of all tabular results appears above the plot results.

plot the three results as shown below.

If acceleration is needed this can be derived by differentiation using the mathematical operations for afu graphs.

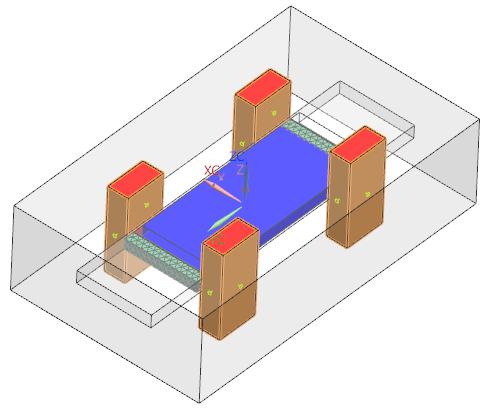

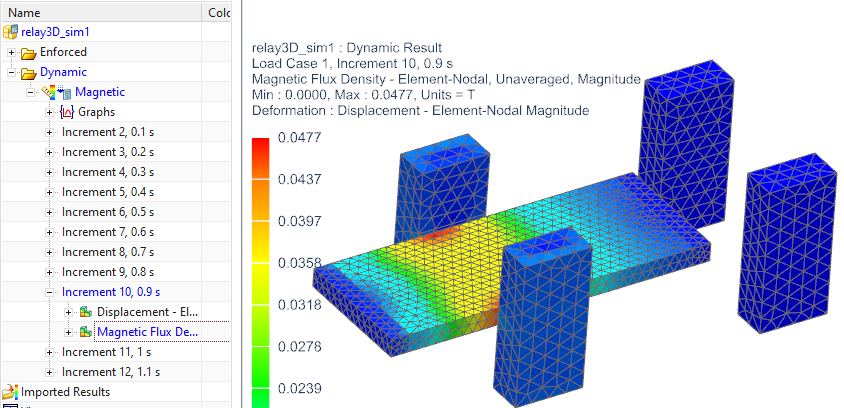

Next we check the plot results. After 10 time steps the Magnetic

Flux density field on the slider should look as follows

This ends the tutorial.